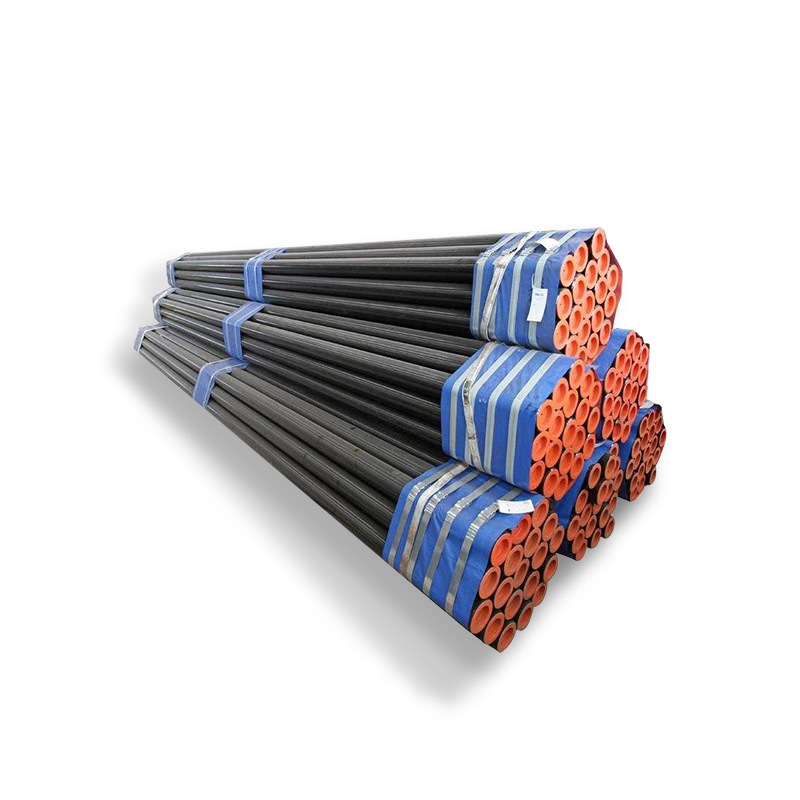

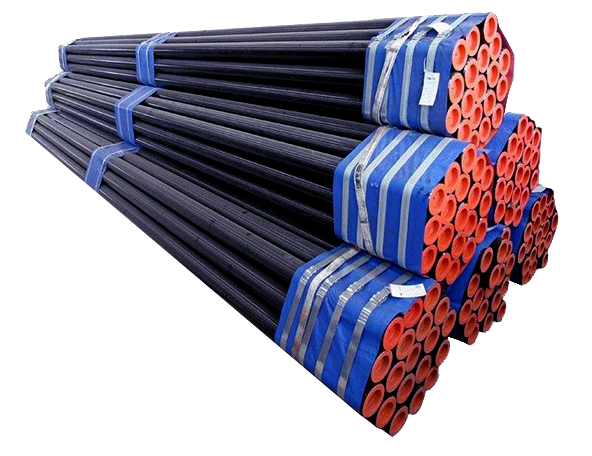

Seamless Steel Pipe Supplier from China

API 5L Steel Pipe

PRODUCT PARAMETERS

API Spec 5L is an international standard that defines the manufacturing requirements for two product specification levels (PSL 1 and PSL 2) of seamless and welded steel pipes. These pipes are primarily used in pipeline transportation systems within the oil and gas industry.

API Spec 5L is an international standard that defines the manufacturing requirements for two product specification levels (PSL 1 and PSL 2) of seamless and welded steel pipes. These pipes are primarily used in pipeline transportation systems within the oil and gas industry.Description

API Spec 5L Steel Pipe Description

API Spec 5L is an international standard that specifies the manufacturing requirements for two product specification grades (PSL 1 and PSL 2) of seamless and welded steel pipes used in pipeline transportation systems in the oil and gas industry.

Product Parameters

| Product Name | API Spec 5L Steel Pipe | |

| Standard | EN/DIN/JIS/ASTM/BS/ASME/AISI etc. | |

| Outer Diameter | Seamless: 1/4″-36″ | Welding: 21.3mm-3620mm |

| Round Tube: 1/2″-10″ | Square Tube/Rectangular Tube: 15x15mm-400x600mm | |

| Wall Thickness | Seamless: 1.25mm-50mm | Welding: 1.65mm-65mm |

| Length | 3-12 meters, Support customization | |

| Surface Process | Bright, Polished, Black | |

| Other Services | Machining(cnc), Centerless Grinding(cg), Heat Treatment, Annealing, Pickling, Polishing, Rolling, Forging, Cutting, Bending, Small Machining, etc. | |

Chemical Composition

| API Spec 5L PSL1 | Brand | C | Mn | P | S |

| B | ≤ 0.28 | ≤ 1.20 | ≤ 0.030 | ≤ 0.030 | |

| X42 | ≤ 0.28 | ≤ 1.30 | ≤ 0.030 | ≤ 0.030 | |

| X46 | ≤ 0.28 | ≤ 1.40 | ≤ 0.030 | ≤ 0.030 | |

| X52 | ≤ 0.28 | ≤ 1.40 | ≤ 0.030 | ≤ 0.030 | |

| API Spec 5L PSL2 | B | ≤ 0.24 | ≤ 1.20 | ≤ 0.025 | ≤ 0.015 |

| X42 | ≤ 0.24 | ≤ 1.30 | ≤ 0.025 | ≤ 0.015 | |

| X46 | ≤ 0.24 | ≤ 1.40 | ≤ 0.025 | ≤ 0.015 | |

| X52 | ≤ 0.24 | ≤ 1.40 | ≤ 0.025 | ≤ 0.015 |

Mechanical Properties

| Standard | Brand | Yield Strength(MPa) | Tensile Strength(MPa) |

| API Spec 5L PSL1 | A25 | 172 | 310 |

| A | 207 | 331 | |

| B | 241 | 414 | |

| X42 | 290 | 414 | |

| X46 | 317 | 434 | |

| X52 | 359 | 455 | |

| X56 | 386 | 490 | |

| X60 | 414 | 517 | |

| X65 | 448 | 531 | |

| X70 | 483 | 565 | |

| API Spec 5L PSL2 | B | 290-496 | 414-758 |

| X42 | 317-524 | 434-758 | |

| X46 | 359-531 | 455-758 | |

| X52 | 386-544 | 490-758 | |

| X56 | 414-565 | 517-758 | |

| X60 | 448-600 | 531-758 | |

| X65 | 483-621 | 565-758 | |

| X70 | 552-690 | 621-827 |

Scope of Application

API Spec 5L specifies the manufacture of two product levels (PSL1 and PSL2). PSL refers to the product specification level established for the API 5L standard. Piping specification classes are classified into PSL1 and PSL2. For pipeline standards, PSL1 and PSL2 pipelines have different levels of quality requirements. API Spec 5L pipeline steel plate is used to manufacture pipeline steel pipes that extract oil, steam, and water on the ground in the oil and gas industry.

| Materials No. | European Standard EN 10208-2 | German Standard DIN 17172 | API 5L |

| 1.0457 | L 245NB | You are 240.7 | Gr.B |

| 1.0484 | L 290NB | You are 290.7 | X42 |

| 1.0582 | L 360NB | StE 360.7 | X52 |

| 1.8972 | L 415NB | You are 415.7 | X60 |

| 1.0418 | L 245MB | You are 240.7 TM | Gr.B |

| 1.0429 | L 290MB | You are 290.7 TM | X42 |

| 1.0578 | L 360MB | You are 360.7 TM | X52 |

| 1.8973 | L 415MB | You are 415.7 TM | X60 |

| 1.8975 | L 450MB | You are 445.7 TM | X65 |

| 1.8977 | L 485MB | You are 480.7 TM | X70 |

| USA | Japan | Germany | U.K. | France | Italy | Spain | Switzerland | China | ||

| AISI/SAE | JIS | W‐nr. | DIN | BS | EN | AFNOR | UNI | UNE | SS | GB |

| A570.36 | STKM 12A | 1.0038 | RSt.37‐2 | 4360 | ‐ | E 24‐2 | ‐ | ‐ | 1311 | 15 |

| – | STKM 12C | – | – | 40 C | – | Ne | – | – | – | – |

| 1015 | ‐ | 1.0401 | C15 | 080M15 | ‐ | CC12 | C15, C16 | F.111 | 1350 | 15 |

| 1020 | ‐ | 1.0402 | C22 | 050A20 | 2C | CC20 | C20, C21 | F.112 | 1450 | 20 |

| 1213 | SUM22 | 1.0715 | 9SMn28 | 230M07 | 1A | S250 | CF9SMn28 | F.2111 | 1912 | Y15 |

| 11SMn28 | ||||||||||

| 12L13 | SUM22L | 1.0718 | 9SMnPb28 | ‐ | ‐ | S250Pb | CF9SMnPb28 | 11SMnPb28 | 1914 | ‐ |

| ‐ | ‐ | 1.0722 | 10SPb20 | ‐ | ‐ | 10PbF2 | CF10Pb20 | 10SPb20 | ‐ | ‐ |

| 1215 | ‐ | 1.0736 | 9SMn36 | 240M07 | 1B | S300 | CF9SMn36 | 12SMn35 | ‐ | Y13 |

| 12L14 | ‐ | 1.0737 | 9SMnPb36 | ‐ | ‐ | S300PB | CF9SMnPb36 | 12SMnP35 | 1926 | ‐ |

| 1015 | S15C | 1.1141 | Ck15 | 080M15 | 32C | XC12 | C16 | C15K | 1370 | 15 |

| 1025 | S25C | 1.1158 | Ck25 | ‐ | ‐ | ‐ | ‐ | ‐ | ‐ | 25 |

| A572-60 | ‐ | 1.890 | StE380 | 4360 55 | ‐ | ‐ | FeE390KG | ‐ | 2145 | ‐ |

| 1035 | ‐ | 1.0501 | C35 | 060A35 | ‐ | CC35 | C35 | F.113 | 1550 | 35 |

| 1045 | ‐ | 1.0503 | C45 | 080M46 | ‐ | CC45 | C45 | F.114 | 1650 | 45 |

| 1140 | ‐ | 1.0726 | 35S20 | 212M36 | 8M | 35MF4 | ‐ | F210G | 1957 | ‐ |

| 1039 | ‐ | 1.1157 | 40Mn4 | 150M36 | 15 | 35M5 | ‐ | ‐ | ‐ | 40Mn |

| 1335 | SMn438(H) | 1.1167 | 36Mn5 | ‐ | ‐ | 40M5 | ‐ | 36Mn5 | 2120 | 35Mn2 |

| 1330 | SCMn1 | 1.1170 | 28Mn6 | 150M28 | 14A | 20M5 | C28Mn | ‐ | ‐ | 30Mn |

| 1035 | S35C | 1.1183 | Cf35 | 060A35 | ‐ | XC38TS | C36 | ‐ | 1572 | 35Mn |

| 1045 | S45C | 1.1191 | Ck45 | 080M46 | ‐ | XC42 | C45 | C45K | 1672 | Ck45 |

| 1050 | S50C | 1.1213 | Cf53 | 060A52 | ‐ | XC48TS | C53 | ‐ | 1674 | 50 |

| 1055 | ‐ | 1.0535 | C55 | 070M55 | 9 | ‐ | C55 | ‐ | 1655 | 55 |

| 1060 | ‐ | 1.0601 | C60 | 080A62 | 43D | CC55 | C60 | ‐ | ‐ | 60 |

| 1055 | S55C | 1.1203 | Ck55 | 070M55 | ‐ | XC55 | C50 | C55K | ‐ | 55 |

| 1060 | S58C | 1.1221 | Ck60 | 080A62 | 43D | XC60 | C60 | ‐ | 1678 | 60Mn |

| 1095 | ‐ | 1.1274 | Ck101 | 060A96 | ‐ | XC100 | ‐ | F.5117 | 1870 | ‐ |

| W1 | SK3 | 1.1545 | C105W1 | BW1A | ‐ | Y105 | C36KU | F.5118 | 1880 | ‐ |

| W210 | SUP4 | 1.1545 | C105W1 | BW2 | ‐ | Y120 | C120KU | F.515 | 2900 | ‐ |

FAQs

We offer a wide range of high-quality pipe products, including:

- Hot Rolled Seamless Pipes – Ideal for high-pressure applications in industries like oil, gas, and chemicals.

- Precision Pipes – Designed for high accuracy and smooth surfaces, commonly used in automotive, hydraulic, and machinery applications.

- High Strength Pipes – Built to withstand extreme conditions, perfect for heavy industries such as steel, mining, and construction.

- Special-Shaped Pipes – Customized pipes in non-standard shapes and sizes for specialized industries like aerospace, shipbuilding, and more.

Each product is designed to meet the specific needs of various industries, offering superior quality, durability, and performance.

At Citontek Co., Ltd., we offer flexible and reliable shipping options to ensure timely delivery of our products worldwide. We partner with leading logistics providers to offer the following shipping methods:

- Sea Freight – For bulk orders and cost-effective long-distance shipping, we work with top international carriers for safe and reliable sea freight.

- Air Freight – For urgent shipments, we offer air freight services through global carriers, ensuring fast delivery for smaller orders or time-sensitive products.

- Rail Freight – In regions with developed rail infrastructure, we can arrange rail shipping as an efficient and cost-effective option.

- Road Freight – For local or regional deliveries, we use trusted road transport companies to ensure safe and timely deliveries.

- Express Shipping – For small, urgent orders, we can arrange express services via major couriers like DHL, FedEx, or UPS.

We ensure that every shipment is carefully handled, with full tracking available for all orders to provide visibility and peace of mind to our customers.

At Citontek Co., Ltd., we offer flexible and reliable shipping options to ensure timely delivery of our products worldwide. We partner with leading logistics providers to offer the following shipping methods:

- Sea Freight – For bulk orders and cost-effective long-distance shipping, we work with top international carriers for safe and reliable sea freight.

- Air Freight – For urgent shipments, we offer air freight services through global carriers, ensuring fast delivery for smaller orders or time-sensitive products.

- Rail Freight – In regions with developed rail infrastructure, we can arrange rail shipping as an efficient and cost-effective option.

- Road Freight – For local or regional deliveries, we use trusted road transport companies to ensure safe and timely deliveries.

- Express Shipping – For small, urgent orders, we can arrange express services via major couriers like DHL, FedEx, or UPS.

We ensure that every shipment is carefully handled, with full tracking available for all orders to provide visibility and peace of mind to our customers.

At Citontek Co., Ltd., we aim to make the ordering process as smooth and efficient as possible. Here’s a simple overview of our process:

- Inquiry and Consultation:

Contact us with your product requirements, including specifications, quantities, and any customization needs. Our team will respond promptly to discuss your project. - Quotation and Confirmation:

Based on your requirements, we provide a detailed quotation including pricing, lead time, and shipping options. Once you approve the quote, we proceed with the next steps. - Order Placement:

After confirming the details, you can place your order by signing a purchase agreement or confirming the order in writing. - Production and Quality Checks:

Upon order confirmation, we begin the production process. During manufacturing, we conduct strict quality control checks to ensure the highest standards. - Shipping and Delivery:

Once your order is ready, we arrange for shipping based on your preferred logistics method (sea, air, rail, or road). You will receive tracking information for real-time updates. - After-Sales Support:

After delivery, we offer continued customer support to ensure your satisfaction. We also provide assistance with any queries or issues regarding the products.

This straightforward process ensures that your order is handled efficiently from start to finish, with complete transparency at every step.

At Citontek Co., Ltd., we are committed to providing excellent after-sales service to ensure complete customer satisfaction. Our after-sales services include:

- Product Support:

We offer technical support to help you with product installation, usage, and maintenance, ensuring optimal performance of our pipes. - Quality Assurance:

We guarantee the quality of our products and will address any issues related to defects or non-conformance. If any product does not meet agreed-upon standards, we will work with you to resolve the issue promptly. - Replacement and Returns:

In the unlikely event of any product defects or discrepancies, we provide a clear process for returns and exchanges, including replacements at no extra charge. - Custom Support:

If you have any special requirements or need further customization after receiving your order, we offer support to meet your evolving needs. - Warranty:

We provide warranties on our products, which cover manufacturing defects and certain performance issues. The specific warranty terms are outlined at the time of purchase. - Logistics Assistance:

If there are any shipping or delivery concerns after your order has been dispatched, we assist with tracking and resolving any issues related to the transportation or delivery process. - Ongoing Communication:

We maintain open communication with customers after the sale to ensure their ongoing satisfaction, gather feedback, and address any further needs.

Our after-sales service is designed to ensure that our customers experience smooth operations and peace of mind with their purchased products.