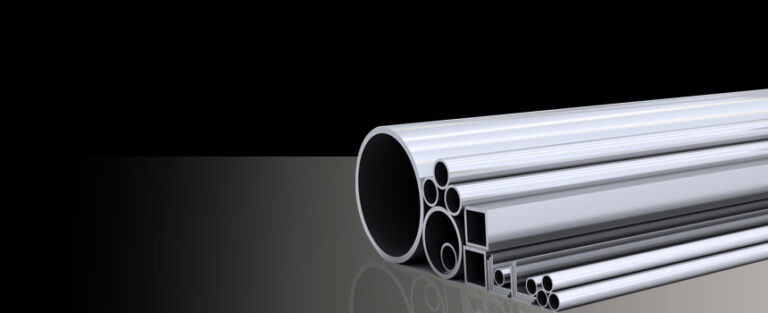

Seamless Steel Pipe Supplier from China

The difference between straight seam steel pipe and seamless steel pipe

The main difference between straight seam steel pipe and seamless steel pipe lies in their manufacturing processes and structural properties:

- Manufacturing Process:

- Straight Seam Steel Pipe: This type of pipe is made by welding a steel plate or coil along a straight seam. The process involves forming a steel sheet into a cylindrical shape, then welding the edges together to create a seam. This is commonly referred to as welded steel pipe.

- Seamless Steel Pipe: This type of pipe is made by extruding a solid steel billet through a piercing process to form a hollow tube. There is no seam or weld in a seamless pipe, hence the name. The pipe is formed by a process of continuous rolling or extrusion.

- Strength and Durability:

- Straight Seam Steel Pipe: The welded seam is the weak point of a straight seam pipe. Over time, welding can lead to potential issues like weld defects or stress concentration at the seam.

- Seamless Steel Pipe: Seamless pipes generally have superior strength because there are no seams or welds, making them less prone to failure under high pressure or mechanical stress.

- Applications:

- Straight Seam Steel Pipe: These are typically used for low to medium-pressure applications, such as water or gas transmission, and are more cost-effective.

- Seamless Steel Pipe: These are preferred for high-pressure applications and in industries where strength, durability, and reliability are critical, such as in oil and gas, power generation, and chemical industries.

- Cost:

- Straight Seam Steel Pipe: These tend to be more cost-effective because the manufacturing process is simpler and less energy-intensive.

- Seamless Steel Pipe: Seamless pipes are generally more expensive due to the more complex and time-consuming production process.

In summary, straight seam steel pipes are welded and generally suited for lower-pressure applications, while seamless steel pipes are stronger, more durable, and used in more demanding environments.